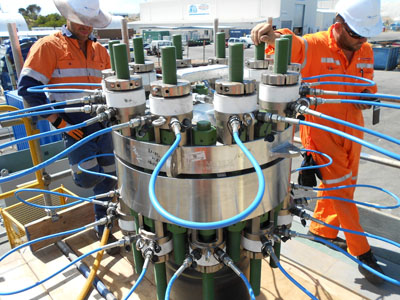

SUB SEA SPOOL & MANIFOLD TESTING SERVICES

SUB SEA SPOOL & MANIFOLD TESTING SERVICES

Process Chemicals has a comprehensive portfolio when it comes to the specialised testing of subsea rigid and flexible spooling and manifolds throughout Australia and abroad.

Our understanding of the extensive variety of Subsea Vendor systems, tie in connections and tools, including FMC, GE, Cameron, One Subsea, Oceaneering and Vecto Gray to mention a few, allows us to manage a broader scope of projects and provide you with the right engineering and field service for practical completion.

We recognise the importance of performing our services correctly and that all works done, comply with relevant standards and legislative requirements, such as AS2885, ASME B31.8 and DNV-OS-F101.

- Development of procedures, oversight, management

- Pigging and Gauging

- Hydraulic Tensioning

- Factory Acceptance Test, Systems Integrity Test and Site Acceptance Testing

- Back Seal Testing

- Load Out Flooding (MEG and Dye)

- Subsea Control Fluid Flushing of Control Lines and Umbilicals

- Function Testing

- Continuity Testing

- Vertical and Horizontal Jumper configurations

- Various shapes – M, U, Z, L customized to meet field layouts

- Single, dual and multibore configurations to cater for production, injection, chemicals and hydraulics

- Umbilicals

- Risers

- Distribution Manifolds

- Pipeline End Terminations and Manifolds (PLET and PLEM)

We offer our customers a fully integrated testing service, tying it all together, from beginning to end and delivering a specialised solution that effectively reduce subsea vendor management and the need for several subcontractors.

Contact us today to about our subsea spool testing services.